Imagine you’re running a factory that makes electric scooters. One day, your team is ready to assemble — but the batteries haven’t arrived yet. Production stalls, deliveries are delayed, and customers aren’t happy.

This is exactly the kind of chaos Material Requirements Planning (MRP) is built to prevent.

MRP isn’t just about tracking inventory; it’s the brain behind balancing what you have, what you need, and when you need it — factoring in stock levels, lead times, and the Bill of Materials (BOM).

It’s how manufacturers keep production running without a hitch, ensuring no material shortages and no unnecessary overstock.

Let’s dive in and see how MRP actually works.

How MRP Really Works: Your Production’s Mastermind

Think of Material Requirements Planning (MRP) as your factory’s ultimate strategist — ensuring every part, every component, and every deadline falls perfectly into place.

At its core, MRP answers three simple but powerful questions:

- What do we need? (Example: Batteries, motors, frames — everything needed for your scooters.)

- How much do we need? (Example: 500 batteries for next month’s production run.)

- When do we need it? (Example: Batteries delivered at least two weeks before assembly kicks off.)

But MRP doesn’t stop at just making lists.

It syncs your supply chain with real-world production schedules — so your manufacturing line never misses a beat.

To operate effectively, MRP pulls data from several key sources:

- Item Name (Nomenclature): The finished product you’re building — say, the “Model X Electric Scooter,” designated as Level 0 in the Bill of Materials (BOM).

- Master Production Schedule (MPS): Your master plan — outlining how many units you need to produce and by when to meet demand.

- Shelf Life of Materials: Managing sensitive materials like lithium batteries? MRP tracks their shelf life, so you order just enough — no waste, no loss.

- Inventory Status File (ISF): A live tracker showing what’s currently in stock and what’s still on the way from suppliers.

- Bills of Materials (BOM): Your product’s DNA — a detailed list of every part and component required for assembly.

- Planning Data: The behind-the-scenes blueprint — covering routing, labor standards, machine time, quality control, and lot-sizing rules to streamline every stage.

Simply put:

MRP isn’t just planning — it’s precision coordination. It calculates exactly what you need, schedules it at the right time, and helps your production floor operate like a finely tuned machine.

Now, think about enhancing your entire material planning process with a robust platform built to deliver unparalleled precision and real-time insights, transforming the way you manage resources. That’s what Eazy ERP brings to the table.

Let’s understand how it can help you in improving your materials requirements planning process below!

Master Materials Requirements Planning with Eazy ERP

Are you struggling to keep your production planning on track?

Eazy ERP makes Material Requirements Planning (MRP) smarter, faster, and more precise — just the way it should be.

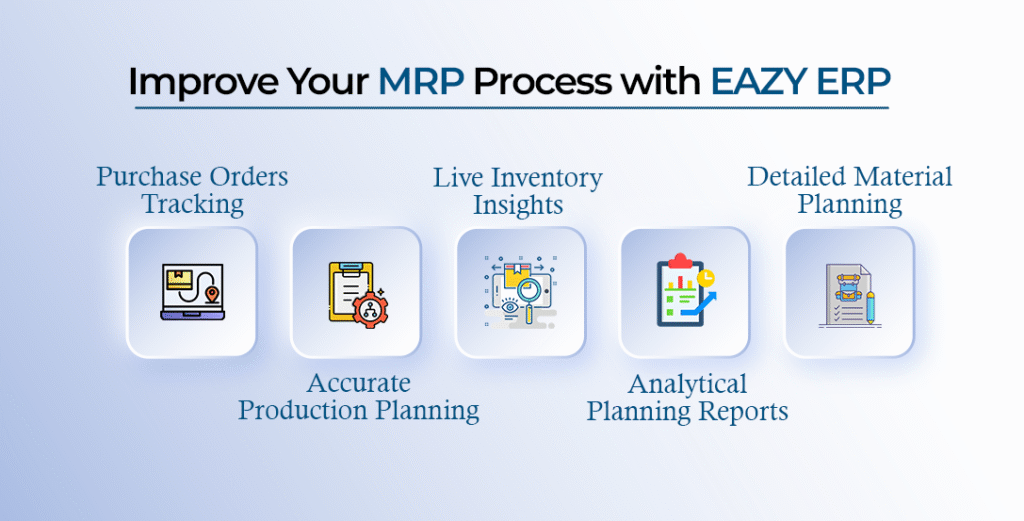

With Eazy ERP, you get a dynamic material management system that simplifies everything:

- Monitor stock availability in real time

- Track finished goods and pending purchase orders

- Plan production accurately — at the lowest possible cost

But we don’t just stop there.

Eazy ERP helps you analyze all production requirements effortlessly and automatically generate purchase requisitions — based on authorization workflows and scheduled timelines.

What else is in store?

- Live inventory insights through intuitive stock reports

- Powerful group-and-sort analytical reports for smarter planning

- Step-by-step material planning that leaves no detail overlooked

With Eazy ERP, you’re not just managing materials — you’re setting up your production for success.

MRP: The Key to Efficient Production Workflow

Achieving perfect production requires precision in material planning, timely inventory management, and a proactive approach to meeting demands. Material Requirements Planning (MRP) enables you to align every part, component, and schedule with pinpoint accuracy. With MRP, your production processes run smoothly, supporting continuous growth and driving operational success, ultimately boosting productivity and profitability.