Ever had your production grind to a halt because one part didn’t arrive on time?

Or looked around your warehouse, wondering why it is filled with materials you don’t actually need?

Yeah, that’s what happens when material planning lacks clarity and direction.

This is exactly where Material Requirements Planning (MRP) steps in. It’s like giving your production process a GPS—making sure every material is available in the right quantity and at the right time of the production stage.

Wondering how it all fits together?

Keep on reading—we’re breaking down how MRP works and how it can help you plan better, move faster, and keep your shop floor running like clockwork.

Let’s get started!

MRP: The Smart Way to Optimize Production

Imagine running a production line where every part and material arrives just when it’s needed—no delays, no last-minute orders, and no excess stock. That’s the power of Material Requirements Planning . It helps manufacturers stay ahead by ensuring the right materials are on hand at the right time, keeping everything flowing smoothly without any delays.

Think of it as your manufacturing GPS. It helps you map out your production needs, avoiding both shortages and overstocking. With MRP, you’re not just reacting to problems as they come up; you’re staying ahead of them.

It helps you keep your supply chain in sync, streamline your operations, and ultimately save time and money.

In simple terms, MRP is all about smarter planning. By using it , you can ensure that your production process runs smoothly, your inventory stays under control, and you can meet customer demand without any trouble.

Now that we’ve covered how MRP keeps your operations on track, let’s take a closer look at why it’s so essential for your manufacturing business.

Why is MRP important for Manufacturers?

If you’re in manufacturing, you know how critical it is to have the right materials at the right time. Material Requirements Planning does just that. With the help of MRP software or ERP systems like Eazy ERP, you can make sure you’re always stocked with exactly what you need—no more, no less—and keep everything running smoothly.

Think about it: when your MRP system is on point, your team becomes more productive, your product quality improves, and your material and labor costs go down. Plus, materials resource planning helps you stay agile, so when demand spikes, you can quickly adjust your plans. No more worrying about stockouts or delays that could cost you customers.

In short, MRP isn’t just about planning—it’s about staying ahead, saving money, and keeping your operations efficient. Having seen the value MRP brings, let’s break down how it functions to keep your production process efficient and effective.

How MRP Keeps Your Manufacturing on Track?

Material Requirements Planning is like the brain behind your manufacturing process, ensuring that everything runs smoothly. It takes data from your Bill of Materials (BOM), inventory records, and Master Production Schedule (MPS) to figure out exactly what materials you need—and when you need them.

Think of the BOM as your “blueprint” for making products. It lists everything—from raw materials to subassemblies—all organized in a parent-child structure. So, your finished product is the “parent,” and all the parts that go into it are the “children.”

Inventory is split into two main categories: independent demand (finished goods, based on forecasts) and dependent demand (the raw materials and components needed for production). It helps you track all these moving parts, calculate exactly what you need, and account for lead times—whether it’s for getting materials, producing the items, or delivering to customers.

In a nutshell, Material Requirements Planning helps you stay on top of ordering, inventory control, and production scheduling, so you can avoid overstocking, running out of materials, and keep your operations running smoothly.

Now, let’s explore what benefits it brings to your business in detail below.

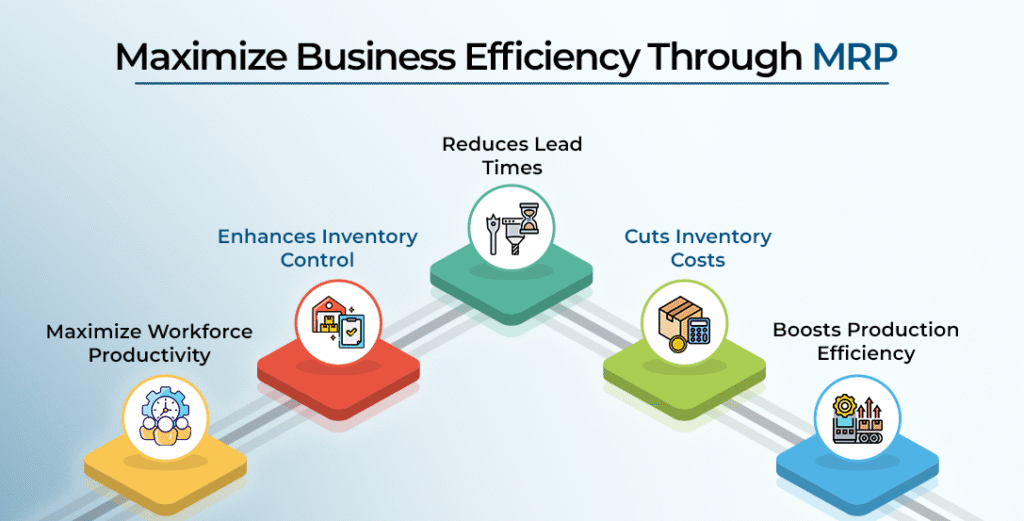

From Production to Profit: How MRP Improves Your Business

The core goal of MRP is to ensure the precise availability of materials in the right quantities at the right time, keeping production on track. But the benefits go beyond just avoiding stockouts—here’s how it can improve your operations:

- Reduces Lead Times: By aligning production schedules with actual demand, MRP minimizes customer lead times, improving satisfaction.

- Cuts Inventory Costs: MRP optimizes inventory levels, reducing excess stock and minimizing carrying costs.

- Enhances Inventory Control: Streamlined material planning ensures real-time tracking and smarter stock management.

- Boosts Production Efficiency: Accurate demand forecasting and scheduling help eliminate production bottlenecks and improve workflow.

- Maximize Workforce Productivity: By eliminating material shortages and reducing downtime, MRP helps workers focus on what matters most—getting products out the door.

MRP Unpacked: Inputs and Outputs

Ever wondered how Material Requirements Planning (MRP) turns raw data into a smooth production process?

It all starts with the right inputs and ends with outputs that keep your shop floor running like clockwork.

MRP Inputs – The Essentials That Kick Things Off:

- Demand: Think sales forecasts and customer orders—this is what drives everything.

- Bill of Materials (BOM): A detailed blueprint of what’s needed to build each product, updated in real-time.

- Inventory: A live snapshot of what’s in stock, what’s running low, and what’s ready to go.

- Master Production Schedule (MPS): Your big-picture plan that aligns materials, labor, and machines to meet delivery timelines.

MRP Outputs – The Results That Drive Action:

- Planned Order Releases (POR): Smart suggestions on what to order, how much, and when.

- Order Release Notices (ORN): Actual orders created—either for purchasing or production—based on those smart suggestions.

- Exception Reports (ER): Red flags for any hiccups like late deliveries, stockouts, or overages.

- The Big Why: These outputs help you execute production plans, avoid costly delays, and make sure performance stays sharp.

While MRP systems are all about managing materials and production processes, many people mistakenly use MRP and ERP interchangeably. But the truth is, they serve very different roles in business operations.

Let’s dive into how they truly differ!

MRP vs. ERP: Unpacking the Key Differences

MRP is all about optimizing how raw materials come together to create finished products, focusing on inventory control and manufacturing processes.

ERP takes things a step further, streamlining not just production but the entire business ecosystem—from payroll and finance to procurement and supply chain management, unifying all functions under one roof.

Now that we’ve covered everything about MRP and its impact on your manufacturing operations, you might be wondering how to optimize your MRP process.

Well, EAZY ERP is here to streamline and enhance your MRP workflow.

Let’s dive into how EAZY ERP can help you take your materials requirements planning to the next level.

Streamline Your MRP Workflow with Eazy ERP

Struggling to streamline your MRP process? Eazy ERP is here to revolutionize how you manage materials and production.

With its dynamic material analysis features, you can easily account for stock availability, finished goods, and outstanding purchase orders—ensuring your production plans are always accurate and responsive to real-time needs.

Eazy ERP’s automated purchase requisition system minimizes manual intervention, keeping your inventory levels optimized without the headache. Plus, it offers step-by-step material planning, livestock tracking, and customizable analytical reports—giving you complete control over procurement and production workflows.

With Eazy ERP in your corner, you can eliminate material shortages, boost planning precision, and supercharge your overall business performance.

The Bottom Line

MRP helps manufacturers to optimize inventory, cut waste, and ensure on-time production. When paired with a robust ERP system like Eazy ERP, It takes material planning to the next level—automating processes, boosting accuracy, and maximizing efficiency. Whether you’re aiming to streamline procurement, fine-tune production schedules, or reduce lead times, MRP is key. Investing in the right solution means your business stays agile, competitive, and prepared to meet evolving market demands with ease.

Schedule a demo to see how EAZY ERP brings precision and control to your Material Requirements Planning process.